Introduction to Optical lens

The Optical lens is an optical system that is closely related to the LED and can enhance the use efficiency and luminous efficiency of light. Different lenses can be used to change the light field distribution of the LED according to different effects. Other types of lenses such as lenses for cameras, telescopes, etc. are not within the scope of this article. This article focuses on the secondary condenser lens.

Lens material classification

Silicone lens

- Because silica gel has high temperature resistance (reflow soldering is also possible), it is often used to directly package LED light-emitting devices.

- Generally, the size of silica gel lens is small, 3-10mm in diameter.

PMMA lens

- Optical grade PMMA (polymethyl methacrylate, commonly known as: acrylic).

- Plastic materials, advantages: high production efficiency (can be completed by injection molding and extrusion), high light transmittance (about 93% when the thickness is 3mm). Disadvantages: The temperature cannot exceed 80° (heat distortion temperature 92°).

PC lens

- Optical grade Polycarbonate (PC for short) polycarbonate.

- Plastic materials, advantages: high production efficiency (can be completed by injection molding and extrusion), light transmittance is slightly lower (the transmittance rate is about 89% when the thickness is 3mm). Disadvantages: The temperature cannot exceed 110° (heat distortion temperature 135°).

Glass lens

- Optical glass material, advantages: rich optical parameter characteristics (optional), high light transmittance (97% transmittance at 3mm thickness), high temperature resistance, etc.

- Disadvantages: large volume, heavy weight, single shape, fragile, difficult to achieve mass production, low production efficiency, high cost, etc. Previously, the price of such production equipment was high, and it was difficult to popularize in the short term.

In addition, the shortcomings of glass that are more fragile than PMMA and PC materials require more research and exploration. As for the improved technology that can be achieved, the rigidity of the glass can only be improved by coating or tempering. The light transmittance will be reduced, but it will still be far greater than the light transmittance of ordinary optical plastic lenses. Therefore, the prospect of glass lenses will be broader.

Application Classification

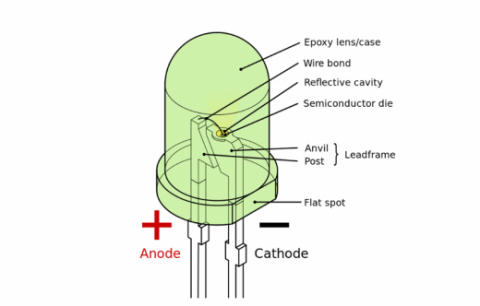

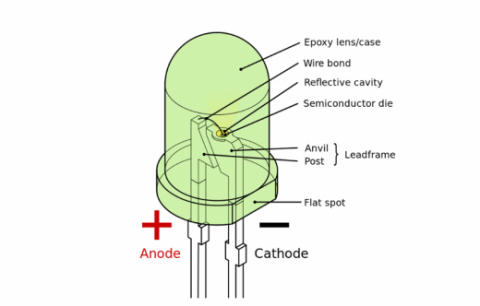

Primary lens

- The primary lens is directly encapsulated (or glued) on the LED chip holder and integrated with the LED.

- The LED chip (chip) theoretically emits 360 degrees, but in fact the chip can be fixed and packaged on the LED bracket, so the maximum light-emitting angle of the chip is 180 degrees (more than 180 degrees, there is a small amount of afterglow).In addition, the chip will have some stray light, so that through a single lens, all the light of the chip can be effectively collected and different light angles such as 180°, 160°, 140°, 120°, 90°, 60°, etc. can be obtained, but The light-emitting efficiency of LEDs with different light-emitting angles has certain differences (the general rule is: the greater the angle, the higher the efficiency).

- The primary lens generally uses PMMA, PC, optical glass, silica gel and other materials.

Secondary lens

- The secondary lens and the LED are two independent objects, but they are indeed inseparable in application.

- The function of the secondary lens is to converge the light-emitting angle of the LED light source to any desired angle between 5° and 160°. The distribution of the light field can be mainly divided into: circle, ellipse, and rectangle.

- The secondary lens material generally uses optical grade PMMA or PC; in special cases, glass can be selected.

Classified by specifications

Through type (convex lens)

- When the LED light passes through a curved surface of the lens (the double convex has a curved surface), the light will be refracted and concentrated, and when the distance between the lens and the LED is adjusted, the angle will also change (the angle is inversely proportional to the distance). The optical design of the lens spot will be very uniform, but due to the limitation of the lens diameter and lens mode, the light utilization rate of the LED is not high and the edge of the spot has a relatively obvious yellow edge.

- Generally used in large-angle (50° and above) spotlights, such as table lamps, bar lamps and other indoor lighting fixtures.

Catadioptric type (cone type or cup type)

- The design of the lens uses a penetrating condensing light in the front, and the tapered surface can collect and reflect all the side light, and the overlap of these two light rays (the same angle) can obtain the most perfect light utilization and Beautiful spot effect.

- Some changes can also be made on the surface of the cone lens, which can be designed into a mirror surface, a frosted surface, a bead surface, a striped surface, a threaded surface, convex or concave surface, etc. to obtain different spot effects.

Lens module

- It is to complete a whole multi-lens lens by injection molding multiple single lenses. According to different needs, it can be designed into a 3 in 1, 5 in 1 or even dozens of lens modules in one; two separate lenses can also be used. Put together by the bracket.

- This design effectively saves production costs, realizes the consistency of product quality, saves the space of the lamp mechanism, and makes it easier to achieve “high power” features.

Loss consideration

1.The luminous flux of lamps with blister and lens should actually meet the light distribution required by the standard, and factors such as the transmittance of the housing and the lens, and the loss of overflow light must also be considered. However, high-power bulbs or general lighting use lenses to diffuse the parallel beams to meet the requirements of the standard.

In order to make the optical effect more reasonable, the lamp housing should be divided into small rectangular units in the design. The purpose of this is to break the wave surface of the light wave and make the product produce a uniform appearance effect.

In each small unit, an ellipsoidal surface is used, because the surface has a radian in both horizontal and vertical directions, so that different radii of curvature can be used in the two directions to achieve different diffusion effects. Its fundamental purpose is to overcome the shortcomings of traditional technology, rationally use light flux, and achieve uniform and efficient light distribution. In fact, the shell of the bulb is made of PC material (completed by injection molding). The spherical, pear-shaped, and cylindrical bulbs are all non-small units, non-planar whole shells, and the light loss is large and the light angle is small.

2.Because one surface of the lens is a curved surface with a radius of curvature in both the horizontal and vertical directions, the incident light can be diffused in both the horizontal and vertical directions. In view of the fact that the radii of curvature of the two directions are independent of each other, the two curvatures can be adjusted separately according to requirements, so that the light output can be diffused to different degrees in the two directions.

Therefore, the use of a lens composed of a two-way curvature surface can distribute light output more freely according to design requirements, use light flux more efficiently, and reduce unnecessary waste and glare. In addition, because of the smooth transition of the curved surface, the lamp has a uniform transition of light distribution and a good appearance.

A completely transparent PMMA lamp or lampshade will cause dazzling or dazzling string light in the center of the light source, but the brightness at the periphery of the light source is rapidly reduced. The lighting of many social occasions and work environments must eliminate this unpleasant atmosphere or minimize the light sources that cause eye discomfort.

3.The projection of each lens unit on the body is rectangular, so that the units can be arranged closely and neatly. The parallel incident light beam undergoes the refraction of the lens unit to form a bilaterally symmetrical uniform diffusion in the horizontal direction and a downward deflection uniform diffusion in the vertical direction. By adjusting the size of each unit in a set of lenses and the radius of curvature in two directions, the distribution of the emitted light flux in the range of different solid angles can be adjusted to achieve the light distribution required by the design.

In view of the role of the incident curved surface is to deflect the light to form diffusion, the specific unit number, unit size, radius of curvature, etc. of each lens group in the product design can be changed according to the actual situation. The actual situation is that the inner grains (divided into small units) on the lens of the high-power lens are all made by the manufacturer, and only the height, angle, and material of the lens are considered when selecting.

4.We choose to place the light source inside the focal point of the lens. The farther the light source is from the lens, the less the luminous flux of the light source collected by the lens, and therefore the lower the efficiency of the lens system. According to the calculation formula of a single convex lens: r=(nL-1)f. Among them, r-convex curvature radius, nL-lens material refractive index, f-lens focal length. When the lens material is selected, the larger the focal length, the larger the radius of curvature.

Under the same lens aperture Φ, the larger the radius of curvature, the thinner the lens. The thicker the lens, the more obvious aberrations will be, which will affect the use effect. Therefore, choose a lens with a larger focal length as much as possible. At the same time, as the focal length increases, the size of the optical system increases. Therefore, the focal length of the lens cannot be blindly pursued. Since the thickness of the lens is not very large, the Fresnel lens is not used to avoid increasing the tediousness and cost of processing.

Mold processing

- Firstly, it depends on the light source (high-power LED). Different brands of high-power LEDs (such as CREE, lumileds, SSC, OSRAM, EVERLIGHT, EDSION, etc.) will have different chip structures, packaging methods, and light characteristics. When the same lens is matched with LEDs of different specifications and brands, the clubs are different; therefore, targeted development (oriented by mainstream brands) is required to achieve the actual desired effect.

- Use optical design software (such as Code V, ZEMAX, TracePro, ASAP, LighTools, etc.) and mechanical modeling software (such as: Pro/E, UG, SOLIDWORKS, etc.) for design and optical simulation, and continuously optimize to obtain the corresponding optical lens.

- The LED lens itself is a precision optical accessory, so it has extremely high requirements on the accuracy of the mold, especially the processing accuracy of the lens optical curved surface must reach 0.1μm. Generally, the following equipment is required for the processing of such high-precision molds: ultra-precision processing machine (such as PRECITECH NANOFORM 350), CNC integrated processing machine, precision grinder, precision milling machine, drilling machine, CNC precision spark machine, surface profiler and interferometer and many more.

- The most precise part of the mold lies in the optical mold core. First, a special mold core steel (such as Swedish S136 mirror steel) must be heat-treated to 55° to complete the rough embryo. After the rough embryo is nickel-plated, the ultra-precision processing machine is used. Obtained by surface processing.

Material production

- As an optical-grade product, LED lenses have strict requirements on light transmittance, thermal stability, density, refractive index uniformity, refractive index stability, water absorption, turbidity, and maximum long-term working temperature. Therefore, the material of the lens must be selected according to the actual situation. In principle, choose optical-grade PMMA, if you have special requirements, you can choose optical-grade PC. At present, the PMMA material of Mitsubishi is the best (VH001 is the frequently selected grade), while Nantong Liyang, the branch of Mitsubishi in China, is slightly inferior.

- It must be equipped with a dust-free workshop of class 10,000 or higher. The operators must wear anti-static clothing, finger cots, masks and other anti-static and dust-proof measures, and the workshop must be inspected and cleaned regularly.

- It is necessary to have professional optical injection molding machines such as Toshiba, Demag, Haitian, Chen Hsong and other brands, and strictly control the injection molding process to obtain qualified products.

- Product inspection: no bubbles, no depressions, no sink marks, no flow lines, no crescent; shape accuracy Rt<0.005 surface roughness Ra<0.0002.

- The product must be packaged in anti-static and dust-proof PVC, and must be completely sealed. The temperature and humidity must be strictly controlled for storage, and it is best not to store it for more than one year.

From the above LED lens design and production process, the seemingly simple LED lens, from design to finished product, has very high requirements for software and hardware, which also causes the price of LED lenses on the market to vary greatly. Judging from the bright prospect of LED lighting popularization, the market prospect of lens as an essential part of LED lighting lamps will also get better and better.

Advantages

- No matter the distance, the lamp cover (reflector) is not much different from the lens. In terms of uniformity, the lens will be better than the reflector;

- Use a small-angle LED lens, the effect is better than the lampshade, because it needs to be shot far! The lampshade has collected light through the lens (because the LED itself must have a lens) and then pass through the lightshade to collect light, this time will waste a lot For light, it is better to condense the light in the lens, and the light-emitting angle of the lens is easy to handle! Another: if the space is available, using three 1W, the effect is much better than using one 3W!

- In contrast, the lampshade has a wide range of uniform points, but the projection is not good, and the lens is the opposite;

- The LED penetration is more high-end.